Industrial Bearing & Power Transmission Experts. We help get the job done.

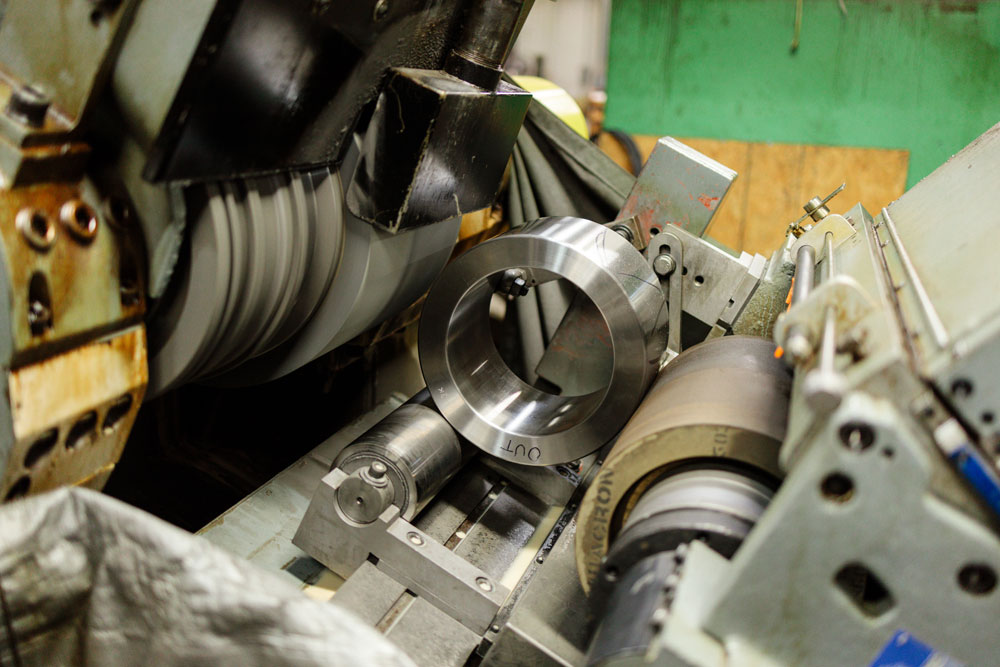

Precision Z-Mill Bearings (Back-Up Bearings)

Our company is a leading manufacturer of new Z-Mill bearings built to precision tolerances that meet or exceed the most demanding industry standards. An uncompromising dedication to quality control, coupled with the most modern equipment, the highest-grade materials, and highly skilled craftsmen provide you with the best performance guarantee in the business.

Manufacturing and Re-Grinding for Z-Mill (Sendzimir) Bearings:

Every Z-mill repair bearing at BSC is identified, cleaned, and dimensionally inspected to generate the proper report with specific bearing information following our ISO guidelines. As with every other repair, there is no cost to the customer, and the rework needed will not be performed until we receive the customer’s PO.

Bearing Re-Grind Procedure

Each bearing is individually polished and cleaned of minor imperfections. Rolling elements are placed in sets and marked so that all components remain matched. In multi-row z-mill bearings, the rollers are marked to be kept in the same order and row. The components go through multiple levels of vibratory tumbling to remove all debris and create the correct surface finish.

The bearing cages are shot blasted and cleaned or completely replaced, depending on the inspection results. The bearing is then reassembled for OD grinding. First, the OD is rough ground and checked for run-out. Bearings are then matched to T-section heights to achieve the correct sets according to customer requirements. Finally, bearings are ground to a finish on the OD to the correct section height before they are etched with a new number and marked individually in the final inspection report.

Final Inspections

The final reports are generated using new section heights comparing the old versus the new OD dimensions, and all other pertinent information is given to the customer for tracking. This report is sent back along with the bearings to the customer, and everything is documented in our system following our ISO guidelines.

An Overview of Sendzimir Bearings: Back-Up Bearings for Steel Rolling Mills

Z-mill or Sendzimir bearings, also called back-up or backing bearings, are specialized rolling-element bearings used in the modern metalworking industry. Typical applications include cold rolling mills and other industrial mill operations that produce rolled steel products.

Back-up bearings are designed to withstand the extreme operating conditions and heavy loads involved in the industrial metal rolling process. In typical mill operations, the roller bearing is used to provide immense pressure to the workpiece metal, shaping it and reducing its thickness as it passes through the mill.

Precision-built Z-mill bearings are critical to ensuring that the work rolls continue to rotate smoothly and reliably. As such, the bearing components are specially engineered to meet the challenges posed by the severe working conditions, including extremely high loads and mechanical stress.